The All-FRP House

The StartLink demonstration house is an all-FRP house. Not just in the big things, either: the structural aspects are literally all-FRP. No steel, not so much as a screw. No concrete, including the foundation.

The project had it genesis in 2004 with a paper delivered at Swansea University in the UK by Mark Singleton to the Network Group for Composites in Construction. It concerned the potential for pultruded FRP in architecture. Singleton was joined by John Hutchinson, and together they began to develop the concepts for an FRP building system. They received research and development support from the The Technology Strategy Board (TSB) and the University of Warwick.

The result is a proof-of-concept house located in Lincolnshire, UK, a two-story structure that meets Passivhaus standards of energy efficiency. You can see models of the structure here.

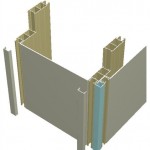

The design of the system features a foundation of FRP tubes driven into the ground as piles. Says Singleton, “Smaller tubes are grouted into the tops to support a FRP ground beam structure that is anchored down with threaded FRP rods, also grouted into the piles. FRP floor cassettes and two storey wall panels are connected to the ground beam and each other to make a portal frame structure. The builders say the floors are more rigid than concrete beam and block (which is good) and this type of foundation also resists flooding, which seems to happen more frequently these days. FRP dowels were used instead of nuts and bolts (which don’t work so well in FRP because it isn’t malleable), so the whole structure is built without steel or concrete. We also used cork cores in the outer wall panels (surprisingly good thermal resistance) which are bonded to studs to make a thermally/structurally efficient wall.

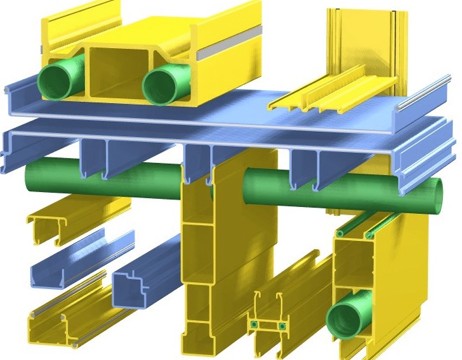

Pultrusion is the science of pulling FRP through profile dies to make long members. The profile-shapes can be quite complex. The main framing of Startlink construction are members whose profiles snap together, making steel fasteners unnecessary.

Startlink’s creators emphasize the sustainable aspects of the system, especially its use of heating and cooling energy. The systems provides highly airtight construction, and minimizes thermal bridging. Moreover, the materials are not affected by water and do not support mold-growth, which is seen as a major advantage in the face of increasingly extreme weather events. If your Startlink house flooded and filled with mud, you could theoretically hose it out and go on with your life. (Of course, if your possessions were not all FRP, they might suffer some damage, but you’d still have a house.) It is lightweight, and the foundation design allows it to built above the expected water-level. (Although you have to ask yourself, if high water levels are expected, why not just build further inland?) Another plus is that FRP is of absolutely no interest to termites.

The system is seen as an economic alternative to traditional construction, since the materials are made and partially assembled into modules off site in the factory. The house is alike a pre-fab kit. Onsite erection is claimed to take less than one week. The designers also boast that it fully recyclable after its service life is completed.

The demonstration house was built in partnership with Exel Composites, and you could order one of the existing designs if you wanted. It was built by Larkfleet Homes, part of the Larkfleet Group, on property adjacent to their headquarters in Bourne.

In the future, it will be possible for other architects to design with the system, as well.

- Image via www.bournelocal.co.uk/

- Image via www.reinforcedplastics,com

Comments are closed, but trackbacks and pingbacks are open.